This article by Mark Albert originally appeared in Modern Machine Shop magazine.

If you want to know how well a machining job shop is doing at communication, talk to the people who do the estimating and quoting. Although every function in a shop calls for the exchange of timely, reliable information, the quoting and estimating processes are especially dependent on getting all the right information from the right sources at the right time. A prompt and accurate quote can’t be prepared without input from others with critical insights into machining processes, cutting tool considerations, workholding and fixturing options, CNC programming strategies, and the work of other inside collaborators. Even for the most expert and experienced quote preparers, the challenge of information gathering and processing can be difficult.

This was the situation at C&M Precision Tech, a provider of CNC lathe machining, Swiss-type machining and other precision machining services. Located in Hudson, New Hampshire, C&M has customers in a range of industries — aerospace, defense, medical and electronics to name a few — all having in common the requirement for high-precision components, especially round parts as large as 4 inches in diameter and 9 feet in length.

Dan Villemaire, C&M’s president and owner, says he will put his team of quoters and estimators up against any company’s in the industry. Yet even with this confidence, he recognized that quoting and estimating were often more art than science, mainly because the processes involve a welter of detail about such factors as ever-changing machine capabilities, improved cutting tools, advances in material characteristics, updates to programming software, shifting regulatory and environmental considerations, and even the varying skill levels of specialists and technicians on the shop floor.

There also was a general awareness that the success of the shop’s efforts to maintain leadership in the high-precision parts manufacturing field could be tested and judged by how well its estimators and quoters could do their jobs. The general feeling was that if the company excelled at the quoting and estimating functions, this reflected an overall excellence in how well everyone in the shop was communicating, collaborating and maintaining a commitment to customer satisfaction.

For this reason, C&M recently had been reviewing its tools and procedures for quoting and estimating with keen attention. “It’s easy to assume that this is an area that every shop struggles with and that we are all in the same boat, so accepting the status quo is the norm,” says Gene Fantozzi, the shop’s lead quoting specialist.

This thinking soon began to change as the shop started talking to newcomers in the quoting software field. The system developer that impressed them the most was Paperless Parts, a company that entered the field in 2017 with software features that C&M could see were based on fresh insights into the quoting and estimating processes. C&M began implementing this system in February 2019 and is currently using every feature in the software.

“C&M really liked our software,” says Jason Ray, president and cofounder of Paperless Parts, “but they came back to us with this constant message: ‘What we really need now are better communication tools.’” The users at C&M could show the Paperless Parts development team many instances in which shortcomings in shop communication were a root problem. “Sure, they were generating more complete, more timely and more flexible quotes with our system, but the challenge of getting the right information from the right people at the right time was still a struggle,” Mr. Ray explains.

In response to C&M’s insistence, the developers at Paperless Parts were tasked to develop a new suite of software communication tools that not only complemented its existing estimating system, but also made overall shop communication more effective. Called “Collaboration,” this suite of communication tools was quickly adopted at C&M, which became a sort of beta test site for the new software.

Commitment and Context

A family-owned company in business for more than 40 years, C&M has a long history in the challenges of accurate quoting and fluid shop communications. “My father and grandfather started the shop with a partner in 1979. It was your typical screw machine shop with cam-operated Brown & Sharpe machines. My father, Paul Villemaire, was the patriarch of the operation while my grandfather, Sam Cole, ran the shop floor, and my father’s Marine Corps buddy Roger Martin, ran the office — hence the company was named C&M for Cole and Martin,” Dan Villemaire says. Mr. Villemaire joined the company in 2006 as the third generation on the management team.

This development marked several turning points for Mr. Villemaire, his father and the company. A year earlier, the elder Mr. Villemaire was facing a serious health crisis that made his full-time involvement in the company a question mark. At the time, his son was entering his last year in college as a finance major. At a crossroads in both his education and choice of careers, the younger Mr. Villemaire opted to switch the emphasis of his studies to operations management and make a commitment to the future of the family business.

He cites a number of factors that affirmed this decision at the time. For one, C&M historically had maintained a policy of renewing its manufacturing resources to stay up with machining technology. For example, the shop began shifting away from cam-operated machines to CNC machines in the 1990s. It now operates nearly 75 Swiss-type CNC lathes from Star, Citizen and Tsugami. These are complemented by large CNC turning centers from Miyano, Eurotech and Hardinge.

Another factor was the company’s legacy of responsible management, which Mr. Villemaire says is characterized by a commitment to serving customers with top-notch quality and on-time delivery, a commitment to teamwork and openness among employees, and a commitment to supporting the larger community. In addition, carrying forward the tradition of family ownership and management was important to Mr. Villemaire.

During the last 14 years, the company has implemented a number of vital management strategies such as lean manufacturing, shop networking for direct numerical control and automated data reporting to an ERP system, and a machine data collection system for monitoring and continuous improvement (all the while strengthening its values in support of the people side of the business and its community involvement).

The progress of these initiatives and a summary of the benefits is well chronicled in this article that appeared in sister publication Production Machining magazine. It is in the context of this emerging digital environment that the shop’s latest advances in streamlined job quoting and shop communication take on their significance and value.

Fast and Accurate

One of the most important lessons Mr. Villemaire says he learned from lean manufacturing is that almost any process or procedure can be analyzed to find waste, especially the waste of time. “Because we were becoming more aware that quoting was a bottleneck, we started analyzing what was happening between the time we received a request for a quote and the time an order was placed,” Mr. Villemaire recalls. Working closely with him in this analysis were Mr. Fantozzi and Rick McQuaide, who jointly lead the quoting team at C&M and have more than 40 combined years of quoting experience.

A useful tool in this analysis was a value stream map, a lean manufacturing technique that pictures the flow of parts across machines and processes to identify bottlenecks. Instead of tracing parts, a value stream map that looked at the steps needed to complete a quote was created. Right away, this analysis hit a nerve with Mr. Fantozzi. As he noted, quoting usually involved too many steps, both literally and figuratively. “Often, the quickest way to move a quote along was to make numerous treks to different expert sources for essential information. I would walk to the desk of a process engineer, to a programmer’s cubicle, to the machinist, to the setup person or to the tool room clerk. That was a lot of walking, and not every trip paid off,” he says.

Two facts stood out starkly from this analysis, as he recalls. One, taking too much time on a quote was robbing the shop floor of precious lead time if the quote was accepted. Two, the only way to reduce the waste involved when a quote was not accepted was to reduce the quoting time. “More quotes in less time became the apparent strategy for making headway in the quoting bottleneck. The result would be a net increase in jobs reaching the shop floor,” he says.

As it happened, things were coming to a head around the beginning of 2019. Mr. Villemaire had just learned about Paperless Parts and its quoting system from a local manufacturing advisor whom he followed on social media. That tip led to an invitation to have the company demo its quoting software, a demo that was positively received. C&M decided to become a customer. By May, the shop was using the system to issue almost all of its quotes.

“This software works for us because it automates many of the quoting tasks. However, preparing a quote not only has to be very quick, but also it must be a reasonably accurate process,” Mr. McQuaide says. According to Mr. Ray, Paperless Parts quoting is a streamlined method for “packaging” the quote online to generate it in an attractive, customized format. This way, a detailed quote can be emailed in very little time. Mr. Ray reports that current shop users, including C&M, are often getting customer orders placed in fewer than two hours using the integrated online ordering system.

To derive an accurate quote quickly, Mr. Ray explains that his company has developed an “intelligent pricing engine” designed to interpret a CAD model and apply cost variables in a template configured by the shop to reflect its capabilities and constraints. This engine, he says, combines algorithms based on part geometry as well as knowledge of the shop’s most experienced estimators. Additional formulas provide the figures for expedited options that consider the impact of lead times on overall shop scheduling and capacity.

Mr. Fantozzi agrees that generating figures for expedited service is a handy innovation. “We can convey the value of our production time to customers by communicating clear, unambiguous options for expedited service. That way, if the customer needs to move up a delivery date, there is no question about a surcharge that may be added,” he says.

“Maybe it is because we were pleased with the results of our transition to automated quoting that we began to wish for more,” Mr. McQuaide says. He and Mr. Fantozzi were soon compiling a wish list of digital capabilities that could enhance or complement the new software. The focus was on communication, such as automating the collection of information from sources within the company. “We were still taking too many steps, too many trips to too many people in various departments,” Mr. Fantozzi says.

Starting the Conversation

Mr. Ray, who had made a number of personal visits to C&M during the signup and installation of the Paperless Parts system, was soon in on the conversation about this growing wish list. “Listening to customers is a great way to learn, and we were learning a lot from C&M,” Mr. Ray says. “The Paperless Parts development team and I quickly recognized that this shop was asking for capabilities we could provide by building out the digital communication tools our quoting system was already based on.”

Mr. Ray says this new suite of communication tools is based on three key concepts. “It has to provide a means to manage all of the conversations that estimators and quoters must have to get the information they need. The way to manage these conversations is to make them savable, shareable and searchable. That’s one key concept.”

Mr. Ray continues, “The second concept is that the tools have to maintain a consistent and coherent context for these conversations based on a growing consensus of the best way to make the part. This involves what we call a technical data package as a repository of digitalized information with controllable network access. Finally, the tools have to protect the security and the integrity of the part data by allowing the distribution of only the information needed by the parties accessing it, whether inside or outside the shop.”

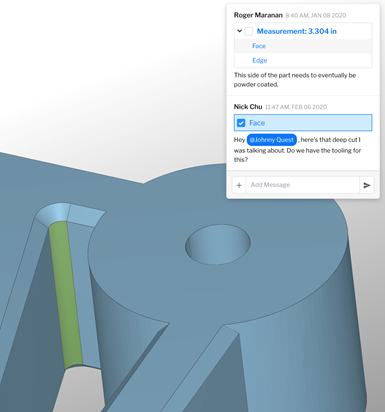

Calling this suite of communication tools by the name of Collaboration is appropriate, Mr. Ray says, because it is essentially an online method of conducting chat sessions among the individuals who need to be involved in the information-gathering process required to issue a quote. “It is a bit like instant messaging with capabilities tailored to the needs of contract manufacturers.” He explains that the system enables users to attach, embed or link to the visual elements that need examination. These include 3D CAD models or selected portions of these models (a universal 3D viewer is included in the system), 2D sketches, snippets from cutting tool or fixturing catalogs and other digital images. When viewing, users can select, highlight and annotate specific features or dimensional callouts for special attention. Rotating, zooming or cross-sectioning the 3D models facilitate visualization and comprehension to reduce chances of misinterpretations or overlooked details. Alerts and reminders can be set up for follow ups that encourage timely responses to inquiries, as well.

“What’s important is that this dialogue, the back-and-forth exchange of ideas, answers to questions or general comments, is captured and saved much like a topic thread in email. Messages in Collaboration can be copied and forwarded. They can be searched by subject, date, name of sender or recipient,” he says. “We’ve also developed a means to digitally associate all the related chat sessions in one directory on a shop’s network. All of the digital information about the part being quoted can be stored and made accessible at this technical data package, as we call it,” Mr. Ray says. This, he continues, creates the context from which a complete and accurate quote can be derived because it distills the best collective thinking and most experienced judgment about the shop’s capability to make a specific part.

Access to contents of the technical data package is controlled, Mr. Ray points out. Passwords and multiple levels of authorization keep the shop’s data and the customer’s data secure. Discrete channels can be set up to share digital information with parties outside the company so they can participate in the conversations with the same ease as those inside, yet without compromising the integrity of protected data or the internal network. He says this enables the shop to share only the information needed for review by subcontractors, noting that the system is ITAR/NIST compliant.

Using the feature tagging capabilities, a specific feature or group of features can be highlighted and called out for ease of understanding in the conversation. For example, drilled holes that must be masked for plating can be tagged so a subcontracting plater can determine the service cost to be included in the quote without risk of missing the feature on the 2D drawing. This reduces mistakes caused by miscommunication, Mr. Ray says.

Implementing Paperless Parts Collaboration at C&M has multiple benefits, as Mr. Fantozzi and his colleague, Mr. McQuaide, enumerate from their experiences with it. One, obviously, is far less walking and talking to gather information, thus saving time and energy for numerous employees throughout the company. Another is better answers to critical questions. Viewing the part model for example, helps programmers spot features that will be difficult or impossible for which to create a tool path or to hold tolerances when machined. Tool clearance issues can be spotted and avoided more easily. The need for special tooling can be checked and verified as “yes” or “no.” Fixturing problems can be anticipated and resolved.

This point leads to another major benefit on their list: fewer “bum” quotes that become headaches, schedule killers or money losers when the job reaches the shop floor. (“Suboptimal quotes are a leading cause of lost profits” to paraphrase more colorful remarks about this point that might be overheard at C&M.) Likewise, avoiding the resulting finger-pointing or recriminations goes a long way toward maintaining company morale.

Yet another benefit is fewer chances that lessons learned during the job run will be lost or overlooked if a repeat order is received. Comments, suggestions and recommendations can be posted in Collaboration at any time during the quoting and production cycle.

What’s Next?

The new quoting system and related communication tools are enabling C&M to cope with emerging challenges and opportunities, Mr. Villemaire says. One of these challenges is the trend among customers to ask for quotes on parts that are of increasing complexity. He attributes this trend partly to the shop’s efforts to offer more manufacturing processes that add value to the customer’s part. Milling operations with live tools on multiple turrets, for example, represent a large portion of this growing complexity. Laser marking, assembly, special cleaning and other added steps exacerbate this situation.

“This trend had been making our former approach to quoting less workable and more problematic, whereas today we can go after these jobs more aggressively and with greater confidence because we can confidently match our capabilities to the demands of this complexity when we prepare the quote,” he says.

Perhaps the most important development on the horizon that has gotten a boost from the new quoting system and communication tools is the company’s proposed move to a 10-hour per day, four-day workweek. According to Mr. Villemaire, this concept has been under consideration for several years at C&M. One of the factors in making this decision is the fact that the extended day shift will allow machinists to run jobs longer after initial setup or morning startup routines. He says that with the current, conventional eight-hour per day, five-day workweek, startup and setup procedures have to be repeated more often compared to the proposed work schedule. “What-ifs” tested with the quoting software and the ERP system indicate that the advantages of the four-day week are significant in terms of cost and time savings.

Mr. Villemaire reports that employees at C&M have expressed considerable enthusiasm for this proposed change in the workweek. They favor it because it supports a better work/home life balance, creates more family time during the extended weekend and makes Friday a more logical, less-intrusive time for the inevitable overtime that must be scheduled.

Yet, as it stands, Mr. Villemaire sums up the current impact of faster, more accurate quotes and smoother shop communication: “We are winning more jobs. We have less friction between departments. Company revenue is on an upswing.”