This article by Eli Plaskett originally appeared in Modern Machine Shop magazine.

Peterson Machining is a quintessential job shop. Not only does it perform high-mix, low-volume work, but it is a family-owned shop that works through personal connections to suppliers and customers, and the owners stamp their personality onto it — including stenciling nicknames onto machines and keeping a classic Mustang in one of the bays.

Being small and family oriented, however, does not mean being low tech. The shop runs on exacting standards, using best practices at every opportunity to improve standards and open up new work. Lately, this has involved investing in automation systems for low-volume work, as well as moving towards lights-out production.

Small Shop, Big Ambitions

Todd and Ronda Peterson, who co-own the company, founded Peterson Machining 30 years ago on the outskirts of Boulder, Colorado. Initially running a single machine tool out of a single bay in an industrial park, the company now owns the building and makes use of nearly the entire space, even if some of that space goes to Mr. Peterson’s Mustang.

Like many job shops, Peterson Machining takes on quite a bit of prototyping work in addition to a handful of high-production orders. Roughly 95% of the company’s business is cutting aluminum for the aerospace and radio-frequency industries, though it also takes on stainless, titanium and magnesium parts on occasion. One point of pride is a part the company cut for a NASA mission to Mars, which turned a 146-pound block of aluminum into a 6.2-pound part.

Often enough, what can seem like an interesting quirk has real business applications. Why does the company name each machine? According to Mrs. Peterson, it makes it easier to trace any problems found in quality inspection back to the source. Why does the company purchase its machine tools in matching pairs? If the shop has to take one offline for repairs, it can keep the other one running. The Petersons stamp their personalities onto the shop, and by doing so improve its functionality.

While the company’s workload has grown considerably over the years, it only has nine employees and eight machine tools. Despite this small size, Peterson Machining recently participated in the MMS Top Shops survey and was in the top-performing benchmarking group. It has been able to grow and thrive with such limited numbers thanks primarily to the Petersons’ dedication to investing in technology that maximizes the capabilities of their workers.

The Peterson Guide to Machine Purchases

The Petersons take great pride in the growth and success of their company, which they in part attribute to the careful, meticulous research they put into every machine they purchase. “When we invest in new technology, we vet it carefully,” Mrs. Peterson says. “When we purchase a new machine, we look for technology that lets us to do something we couldn’t do before.”

This ethos means that Peterson Machining consistently invests in improving its versatility. For example, in 2009, the company purchased two DMU 65 MonoBlock five-axis milling centers from DMG MORI. Until this point, the company did not have five-axis capabilities, but rather than jump into any machine that could handle 3+2 milling, Mr. and Mrs. Peterson researched their options.

The Petersons wanted full five-axis machining capabilities, but that alone could not justify the purchase. At least, not to Mrs. Peterson. “Before I let them buy something,” she says, “they have to show me that it will be worth it.” Another important goal was developing automation that could shorten setup times and improve the company’s ability to bring in additional work. The company also needed something that could provide an excellent finish, as well as decent feed rates, and Mr. Peterson spent months vetting his options before choosing the DMU 65s. Following the shop tradition of naming each machine, it named its new purchases Eve-a and Maximilan.

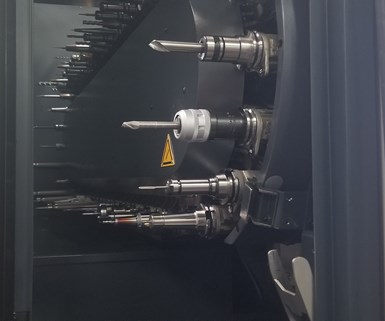

A major selling point for the pair of DMU 65s ended up being the number of available options. The company opted to equip each mill with a 60-tool ATC magazine, as well as a Blum laser tool probe and a touch probe for in-process verification. “For us, automation is about freeing our guys to do more with the time that they have,” Mrs. Peterson says. “The tool magazines are part of that.”

That’s because the high-capacity magazines make it possible for the company to set up all of the tooling for multiple jobs at a time, which means switching out jobs is as simple as switching out the workpiece. This frees the team to set up other jobs, make adjustments to a workpiece or tackle other projects while the DMU 65s are working.

Additionally, the machines’ Heidenhain controls are equipped with Machine Protection Control (MPC) from DMG MORI. This software provides in-process vibration and torque monitoring to improve surface finishes. Additionally, it has a rapid-shutdown function that detects crashes and shuts down the machine quickly, often quick enough to prevent costly damages.

More Than Machine Tools

The Petersons do not simply abide by this ethos when purchasing machine tools, but in all of their purchases. This has led the shop to invest in various strategies focused on freeing up time for its machinists, which in turn has led the shop to improve its productivity. For example, it purchased a Speroni presetter from Big Kaiser, which they named Lux. The presetter enables the shop to set up tooling while other jobs are running, saving time and freeing the team to take on more work.

Additionally, the shop has purchased removable attachments from Big Kaiser called Data Tags, which they can clip onto the tooling. The user prints out a barcode from the presetter and tapes it to the attachment. When the cutting tool gets inserted into a tool magazine, the machinist unclips the attachment and slips it onto a pole attached to the machine that Peterson Machining designed, providing everyone in the shop with a readily accessible inventory of the tools loaded into every machine.

In this example, the Peterson approach pays dividends. Not only does the Speroni make the machinists’ lives easier, but it also improves the shop’s ability to track its tooling inventory and manage its cutting-tool purchases. And it bears repeating that by reducing the setup time, the company frees its machinists to pursue more work and bring more money into the shop. Ultimately, every investment in flexibility and additional capabilities enables the shop to improve its bottom line.

The shop’s latest purchase follows this pattern to a T.

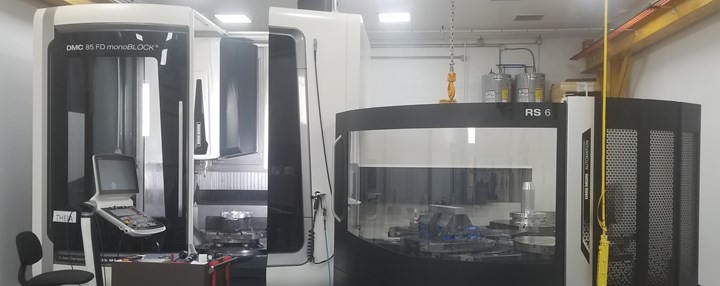

Job Shop Automation

Peterson Machining’s latest purchase is also their largest: a DMC 85 FD Monoblock from DMG MORI. They named it Theia, after a Greek titan, which fits its footprint. It’s a massive five-axis milling machine with turning capabilities, equipped with a 120-tool magazine and a six-station pallet changer. To accommodate the machine, the shop had to lay down a new concrete foundation for the bay, 8 inches thick. In fact, they dedicated an entire bay of their building to this single machine, installing a 2-ton crane and an HVAC system just for it.

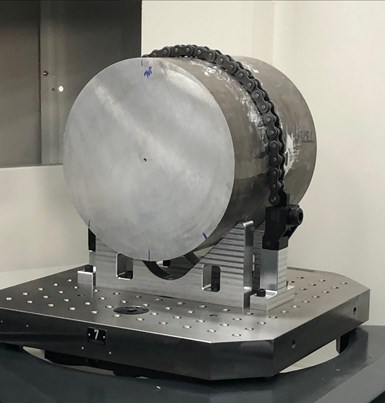

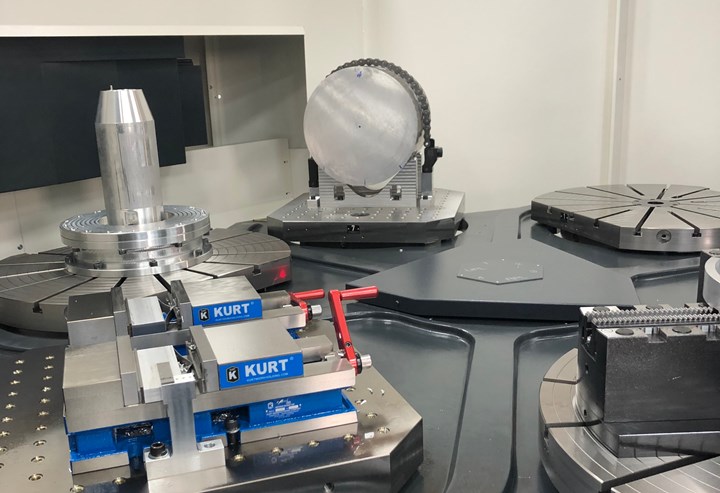

For the Petersons, having both turning and milling capabilities along with a pallet changer opens up new opportunities. “We could have bought a five-axis mill/turn, but we invested in a six-pallet pool, too,” Mrs. Peterson says. “It gives us the opportunity to have three tables for milling and turning, plus three tables just for milling. It expands our opportunities to do different kinds of jobs and work on several things at once.”

So far, the machine has been used principally in large prototyping work, including both turning and non-turning applications. “The pallet changer is really useful for keeping it running while we tinker with work on the pallets,” Mr. Peterson says. “This keeps her making chips while we do prep work for other parts.”

Additionally, if the shop run into difficulty during a job, it can switch out parts and let the machine do its work as the operator makes any needed adjustments. “A lot of shops see automation as something for making lots of parts,” Mr. Peterson says. “But we have had success doing high-mix, low-volume work with the pallet changer because it keeps us productive when we would otherwise have to stop the machine.”

Lead machinist Steve Carper agrees. “It used to be that when a part finished, you had to rush to get the next part loaded up,” he says. “With all of our automation, there is no rush because I’ve already prepared the next workpiece and the tooling. We can get more work done, and I don’t have to drop what I’m doing to keep the machines running.”

Cautiously Moving to Lights Out Prototyping

Another major draw for the DMC 85? Lights-out production for a job shop. “We have been interested in pursuing lights-out machining for a while now,” Mr. Peterson says. “But working lights-out isn’t something you can put together overnight.”

Mr. Peterson recognized immediately that lights-out machining requires a fundamental change in approach. When the company decided unattended machining was a goal to pursue, it invested in Vericut software to ensure that tool paths were perfect. Additionally, it invested in Haimer shrink-fit technology to ensure the rigidity and precision of its tooling. However, that was not enough for Mr. Peterson to feel comfortable machining overnight, but the additional features of the DMC 85 do ease his concerns.

The new machine has numerous functions that make lights-out production more attainable. For starters, the ability to set up pallets and load the tool magazine was needed, but that is not the end of it. As with the DMU 65, the machine came with MPC for vibration monitoring and crash prevention and 3D Quickset, a program for automating the process for establishing the position of the part, further easing fears of scrapped parts or damaged machinery. Additionally, the control came with the new Tool Control Center (TCC) from DMG MORI.

TCC is a system that can detect chips in the work area that can interfere with cuts, in addition to monitoring the cutting edge. Together with MCC, it validates and catches potential problems before they become major issues, preventing chatter and avoiding damage to the tool or spindle. More than that, the TCC software enables the machine to adjust feed rates or switch out tools to compensate for potential problems it identifies, which helps the user to trust a machine tool will do what it’s supposed to.

Even with this system, Mr. Peterson is being cautious. “We are still making sure our setup will be able to handle unattended machining,” he says. “Before we pull the trigger, I want to be certain it will work without a hitch.” This fits the style with which he and Mrs. Peterson run the business: They patiently conduct the research needed to ensure their success with every new investment.