This article by Matt Danford originally appeared in Modern Machine Shop magazine.

I couldn’t remember the last time I’d seen a quick-response (QR) code, yet there it was: A little stamp, somewhat resembling an ink-blot Rorschach-test image, staring back at me from the menu where the drink list should have been. On the road again for the first time since the pandemic, I hadn’t yet realized how common digital menus had become. Nor had I realized the extent to which QR codes — which I had previously dismissed as a decade-plus-old fad — had reemerged.

In the months since that dinner, I’ve noticed a similar story playing out in manufacturing. QR codes and other means of “branding” items with data are not new in manufacturing circles, nor are similar technologies like radio frequency identification (RFID). What has changed is the context in which they are used — specifically, the context of data-driven manufacturing, which is often touted as an answer to supply-chain and labor problems similar to those plaguing the restaurant industry. Any scannable tag or code is a tangible manifestation of a core idea in data-driven manufacturing philosophy: the idea that data should be inextricably linked to and easily retrievable from the physical entity it describes throughout that entity’s lifecycle.

Philosophy aside, manufacturing technology suppliers are incorporating “tag-and-track” systems into their offerings in a variety of creative ways. Here are four examples I’ve encountered recently:

1. Streamlining workflow. Cosen Saws recently introduced a digital work order system called Q-Cut. A dashboard prompts users to select and input job parameters for the generation of a new work order with a QR code, which the saw operator scans to retrieve cutting parameters and other job-specific data. The idea is to eliminate mistakes associated with manual data entry and to streamline workflow by making it easy to scan and load jobs into the machine.

Another example is the Anca Integrated Manufacturing System (AIMS), a modular approach to automating workflows for grinding cutting tools that leverages RFID. Prior to grinding, the machine scans an RFID tag on the holder of each tool blank to retrieve the cutting parameters and data for that individual blank (among other differences with QR codes, RFID tags actively transmit and feature read and write functionality). With this system, large groups of tool blanks can be loaded chaotically, because the machine will load the right program regardless of the blank’s pallet position. Possibilities for flexing a production schedule — by, for instance, inserting an emergency order, or avoiding the need to account for the position of every tool for lights-out machining — are easy to imagine.

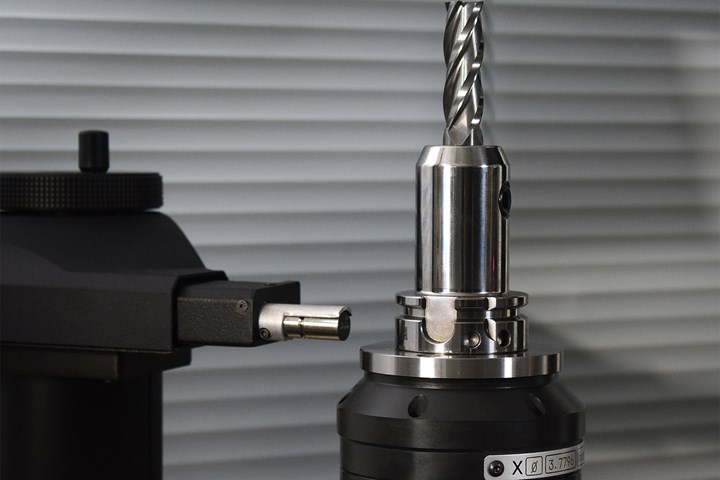

2. Automating and verifying tool setups. Offline presetting of tool assemblies is generally good practice, but it is also a practice that begs to be automated. Presetter manufacturers offer various means of accomplishing this, and most of the ones I’ve encountered employ RFID.

The last time I reported on one of these systems was a 2020 article about Pacon Manufacturing, a California precision machine shop that uses a Speroni presetter from Big Kaiser. RFID facilitates three key advantages in this system. First, offset data calculated from presetter measurements automatically transfer to the CNC. Second, automatic scanning of the tag also helps ensures the right tools are in the right positions of machine tool ATCs with more than 300 slots. Finally, writing cutting time data to the tag enables setting thresholds for issuing tool-life alerts for cutters that might not last through an entire unattended production run.

3. Managing the tool crib. Lost tools, incorrect tool assemblies, selecting the wrong tool — these common machine shop problems present ideal use cases for tag-and-track. One system designed for this purpose, Idem, provides users with RFID tags to affix to tools and scan with a portable reader. The system provides an at-a-glance dashboard view of all tools as well as scan histories; team member notes; compatibility details and more. Data can be sourced directly from an online database that reportedly contains information from more than 40 tool vendors.

4. Reducing saste through productivity improvement. Idem was founded by engineers from Seco Tools, which offers the system through its own Seco Tool Identification program. However, Seco has also been working on another system that uses different technology to achieve different goals. Late last year, the company announced that its Turbo 16 inserts would be laser-printed with data-matrix codes (which look and operate like QR codes but cram more information into the same space, among other differences).

According to Seco, more information on matrix-imprinted tooling is forthcoming. However, an article published by the company last year sheds light on the possibilities — including the possibility of the manufacturer also tracking the tools, which customers would imprint with data on specific machines, operations and run-times before sending the tool back at the end of its life. In addition to helping with customer application support, the data could feed into research and development of new cutting tools. It might also be used to sort returning tools for recycling.