This article by David Lyell originally appeared in Modern Machine Shop magazine.

With a business model sketched out on a napkin at the start of 2017, Greg and Shelly McArthur dedicated their home garage to a new business venture: a CNC machine shop. NTL Industries Inc. would be Greg’s opportunity to take everything he had learned in his 20 years of CNC machining experience and make a go at running his own business from the ground up.

After a year in the garage shop, the shop had the opportunity to upgrade to a larger space in Sterling Heights, Michigan. The move to the new facility was built on a culture of saying “yes” to as many RFQs as possible.

In some cases, saying “yes” involves working with whatever material the customer specifies, even if it falls outside the norm. One recent example was a small plastic part for the automotive industry. The size and shape of the part didn’t immediately lend itself to a fast cycle time, but McArthur was confident that he could make it a profitable part.

Plastic machining requires thinking differently than machining other materials, but McArthur has a simple approach: “I treat it like aluminum, but faster.” Asked for more specifics, he cites the following principles as key to plastic milling success:

-

Avoid the Melting Point

McArthur’s “faster” motto mitigates the thermal issues that often plague plastic operations. This is because plastic — in this case, ultra high molecular weight (UHMW) polyethylene — often has significant problems during milling operations. The melting point is around 260°F, and thermal expansion happens rapidly. If the feed rate were too slow, the material could build up around the cutting edge and start to melt back together. These blobs and hanging bits of melted plastic interfere with the cut and lead to even greater heat buildup, compounding the problem. Running without coolant also promotes faster chip evacuation with the plastic material.

-

Sharp Tools Are Imperative

When cutting any kind of plastic, a brand-new tool is best. This ensures that the material will not absorb any additional friction as result of a dull cutting edge.

McArthur used a 0.25″, 3-flute carbide end mill with a 0.030″ corner radius for all operations on this part, from roughing to finishing. The rounded end of the bit enabled chamfering operations without changing the tool. A final cycle time of 37 minutes made this a profitable part for the shop.

- CAM From the Bottom up

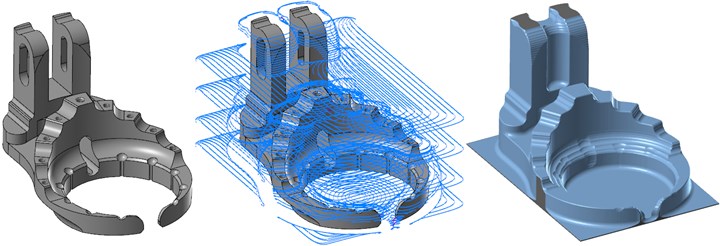

McArthur also cites Mastercam’s Optirough tool paths as critical to making this plastic part a profitable part. This strategy improved cutting efficiency by engaging a larger portion of the end mill’s length, thereby avoiding concentrating wear at the tool tip.

The plastic part was a good candidate for Optirough in part because it has features and faces at different heights, McArthur says. Such geometry facilitates aggressive roughing between the features using as much of the tool flute as possible. For this job, McArthur was able to maintain a 1.125″ depth of cut with a 10% step over. Reducing passes is a common way that NTL Industries seeks to make their processes more efficient, “How can I create this part with the smallest number of passes to get the shape I need?” McArthur asks.