This article by Matt Danford originally appeared in Modern Machine Shop magazine.

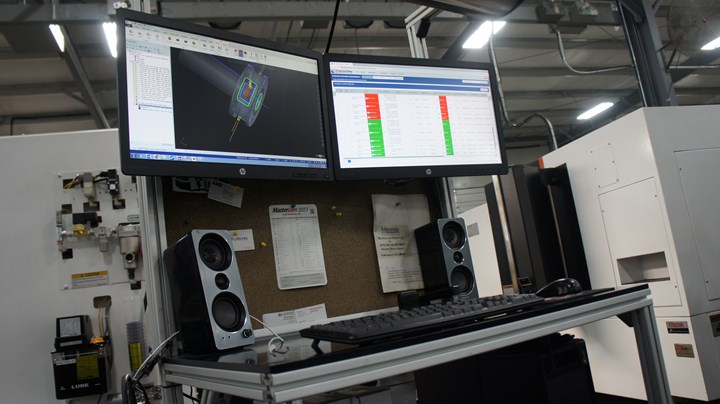

A tour can be telling for anyone hoping to truly understand a CNC machining business. Consider Northwood Industries (NWI), a family-owned, 24,000-square-foot operation in Perrysburg, Ohio. A clean floor, organized workstations, color-coded bin systems and a large board displaying key performance indicators evidence a shop as lean and well-run as any. Similarly, the presence of new multitasking and five-axis machines amid rows of whirring spindles points to financial success, technological sophistication and the flexibility to accommodate a varied mix of demanding work.

However, what truly defines a shop is not always obvious at first. For instance, President and CEO Kurt Miller insists that NWI’s design and engineering expertise is as important as its machining capability in solving problems for customers, which consist mostly of manufacturers in the solar power, automotive, food and plastics industries. More notably for the purposes of this article is the recent transformation in how this 35-employee business manages workflow.

As recently as 18 months ago, shop-clogging work-in-process (WIP) was a more common problem. Confusion about what to do next, whether in terms of the next job or the next operation at a specific workstation, led to a “constant expedite” mode that ramped up stress and made problems worse. Which jobs shipped on time often came down to subjective measures. “Sometimes it was about who was applying the most pressure,” says Patrick Boyle, director of business operations.

All of that changed with the adoption of Production Flow Manufacturing (PFM). According to developer LillyWorks, this system differs from traditional finite scheduling systems in that it is not truly a scheduling system. Rather, the focus is on real-time, shopfloor priorities. Once the software was up and running, NWI saw results within weeks, even before the company began employing the software’s integrated predictive analytics tool to plan and improve. The first seven months of this year, throughput (measured as sales divided by shop hours worked) increased 20%. The average on-time delivery rating is now 96%, compared to 87% before Northwood adopted PFM. “Not all the improvement can be attributed to PFM, but the system has certainly improved the rate at which we are moving jobs as well as the duration of time that work is on the floor,” Mr. Boyle says.

Although it originated as the scheduling module of LillyWorks’ own ERP software, PFM is also available as a standalone module designed to integrate with other shop management systems. NWI opted for this approach. “We’re quite happy with our ERP system,” Mr. Miller says.

Focused on Flow

Before PFM, NWI had always loaded capacity based on product due date. The problem with this seemingly logical approach is that due date alone is insufficient for prioritizing shopfloor tasks. According to LillyWorks, this problem makes scheduling complex and difficult even with the aid of sophisticated software.

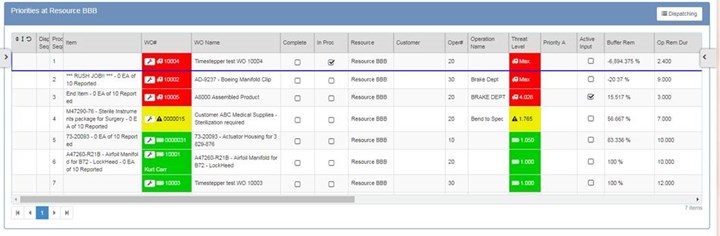

For their part, Mr. Miller and Mr. Boyle say they were intrigued by PFM’s promise of an easier way, and fewer features and settings to consider. The software’s priority system is different because it is blind to capacity, and because the methodology is not organized around due dates alone. Rather, the aim is to answer one critical question: What is most important to do right now, both overall and in terms of specific operations at specific workstations?

At NWI, this laser focus on real-time priorities has eliminated disconnects between what capacity-loading logic tends to suggest and what really needs to happen to deliver on time. For example, intuition might suggest a job due in two weeks should begin before a job due in two months. However, such a decision can have ripple effects. What if the supposedly less urgent (and, perhaps, “quick and easy”) two-month job dictates that parts spend time outside the shop for plating? If the secondary service provider gets busy and the parts’ return is delayed, carefully laid plans fall apart.

Similar scenarios tend to involve jobs that require more processing time than others, or more time in the assembly area. Whatever the specifics, the old system left no room for error. “We were always in a reactive mode, caught in the tyranny of the urgent,” Mr. Boyle says.

“We were always in a reactive mode, caught in the tyranny of the urgent,” Mr. Boyle says.

Now, there is no need for multiple brainstorming sessions to account for the shifting realities of the day, he says. Rather, PFM sets the priorities as soon as estimators enter job data into the ERP system. As work proceeds and things change, the system updates the priority list automatically to ensure attention is directed to the most urgent tasks first.

Buffering Threats

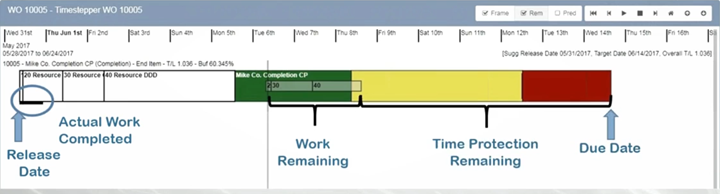

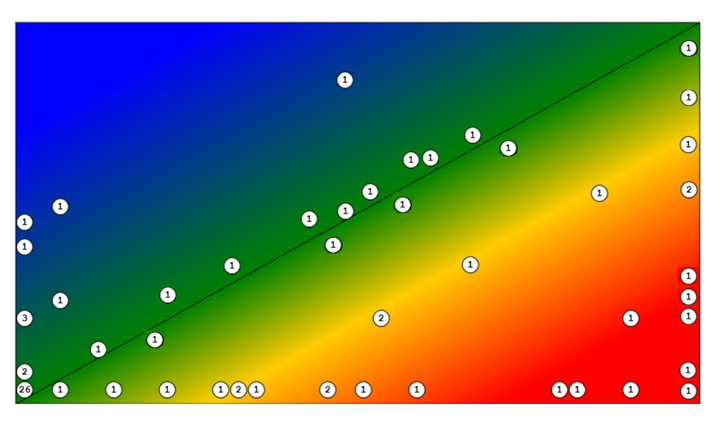

PFM sets and adjusts shopfloor priorities based on the “threat levels” it calculates for every job. Threat levels indicate the relative risk of jobs being late. They are calculated by dividing the percentage of work remaining for the job by the percentage of the job’s remaining “buffer.” Buffers are extra time built into the process to protect the due date — essentially the same concept as starting one’s commute earlier to account for traffic.

The passage of time eats away at the buffers, elevating threat levels. An unexpected delay on one job might raise its threat level even higher. As a result, this job’s operations could move ahead of those associated with other work in shop task lists when the system periodically updates. In contrast, if a job goes smoother than expected, the amount of work remaining declines faster than the buffer. The threat level drops.

Unlike the shop’s previous system, this methodology allows for situations when a job with a later due date is actually more urgent, such as the previous example of parts leaving the shop for plating. As time passes, the buffer shrinks, the threat level rises and the job moves ahead in the priority list. When there is no time left to wait, and the work begins, the necessary capacity is sure to be available. After all, lower threat levels keep less urgent jobs off the shop floor, regardless of their due dates. Later release also ensures these parts spend less time in storage before they ship.

The effectiveness of PFM depends largely on the appropriateness of the buffers. Each workstation has its own buffer, which NWI generally sets according to the average wait time for that station. For instance, NWI’s turning operations generally have longer buffers than milling or grinding because setups are faster and easier.

The buffer for the overall job is the sum of the buffers for each station it crosses. The goal of refining buffers is to ensure jobs release to the shop early enough to meet delivery dates, but late enough to prevent slowing workflow and confusing priorities — that is, to ensure matching inflow and outflow. “Generally, you want to do the work roughly at the same rate that the buffers are being eaten,” explains Tim Rutkowski, milling leader.

NWI continues to refine its buffers. However, Mr. Rutkowski says getting started was easy. As recommended by LillyWorks, the shop used a simple multiplier at first. For example, applying a 3X buffer to a 10-hour job would leave 30 hours in the schedule to accommodate that job. Obviously, this approach was less efficient. Nonetheless, throughput improved within a few weeks as the shop adjusted to the new approach. “This system makes sure jobs get the attention they need when they need it while also avoiding sending too much work into the shop at once,” he explains. “And, there’s a ‘fudge factor’ built in that allows for things to happen.”

“This system makes sure jobs get the attention they need when they need it while also avoiding sending too much work into the shop at once,” he explains. “And, there’s a ‘fudge factor’ built in that allows for things to happen.”

In short, PFM puts execution first. Planning happens later, with the aid of the software’s built-in predictive analysis capability.

Powerful Predictions

Although PFM’s prioritization method is blind to capacity, understanding capacity is essential for any manufacturer. For instance, when can customers expect to receive their orders? What will a given job’s priority be in the future? Even assuming jobs are prioritized correctly, which are most at risk of being late? Can a job be expedited without delaying other work? How well can the shop accommodate additional work in general? What would be the impact of adding another machine tool, or perhaps another shift? The ability to answer such questions can make all the difference in the survival of a manufacturer like NWI.

This is why PFM incorporates predictive analysis capability in the form of a software tool called, fittingly, “The Predictor.” Running in microseconds, the Predictor uses PFM threat-level information along with inventory, capacity and other ERP data to project what workflow will look like at a designated point in the future. Essentially, it simulates the execution of the shop’s entire backlog to predict when every operation for every job will start and finish. The intent is to conduct “what-if” scenarios; to determine what to quote when; to find and break bottlenecks; to refine buffers and other metrics; or to conduct any other analyses required to improve throughput.

The result looks much like a schedule, such as the ones generated by traditional capacity-loading algorithms. The difference, of course, is that shopfloor priorities have already been set by the time The Predictor runs. There is no question about, say, why one job’s changing threat level pushed it ahead of the other because the simulation matches the reality of how work orders will flow through the shop, barring any buffer changes or process refinements. Because the data matches the reality, it provides a better foundation for machine learning (a subset of artificial intelligence), which Lillyworks is currently investigating as a means of augmenting and complementing The Predictor.

For its part, NWI is doing just fine without machine learning. “We can anticipate problems a week or two in advance,” Mr. Rutkowski says. “When we need to quote a lead time, we can take an estimate, and The Predictor will spit out when we would have that job completed. It tells us what will be late, and what might happen if we try to do something about it. I use it constantly to change part routings.”

Process adjustments include both general improvements and on-the-fly tweaks to save time when threat levels rise. In one recent case, miscommunication resulted in an emergency order for 60 parts, and the work was complex. The Predictor revealed the full and exact extent of the devastation to be wrought by inserting this inherently high-threat job into PFM’s priority system.

More importantly, The Predictor provided assurance that moving the emergency work to another machine would enable completing the job on-time without disrupting other work. “Before, we were making a lot of decisions blindly, without knowing all of the effects,” he says.

Ground-Up Growth

Sticking with PFM was more difficult than initial adoption. “We lost traction at one point,” Mr. Miller says. “We weren’t looking at PFM, and we weren’t buffering things consistently. Everybody was going back to what they knew and what was comfortable.”

He says the embrace of PFM by shopfloor leaders like Mr. Rutkowski has helped spur others to consider a system that can seem anything but intuitive at first. For example, it was once common practice to run a single, repeat job long enough to fill not just the customer’s current order, but the next order as well. PFM revealed the error of these ways. “The way to think about this is that it doesn’t make much sense to push parts through only to put them on a shelf,” Mr. Rutkowski says. “That means more setups, sure, but we could look at that as an opportunity to get better at those setups. We could look at setup time as a percentage of overall time and really zero in on that.”

Organizational structure also makes a difference in spreading acceptance of new ways. Mr. Miller and Mr. Boyle discovered PFM at an industry event just a few months after the departure of the shop’s production manager, whose job consisted mostly of scheduling. Rather than rehire for the position, leadership decided to assign area leaders, such as Mr. Rutkowski, to manage workflows. “The cultural aspect of this is huge,” Mr. Miller says. “I didn’t want to be the guy driving it, and Pat (Boyle) couldn’t be the guy doing it either. We needed the whole team to embrace it.”