Win-Tech, Inc. is a modern CNC machine shop located just 30 miles outside of Atlanta in Kennesaw, Georgia. While Win-Tech serves an array of sectors, it specializes in precision machining parts for the aerospace industry.

NTMA recently talked with Allison Giddens, Win-Tech’s Co-President, about the shop’s expertise and capabilities, how it uses NTMA’s network to improve its machine shop management, and where Win-Tech is giving back to the NTMA community.

Win-Tech: Precision Machining with Industry Expertise

Win-Tech has been in business for over 35 years. While the shop began as a tool and die manufacturer, today, the veteran and woman-owned operation specializes in precision machined parts for aerospace applications.

“We’re conveniently located just down the street from the Lockheed Martin hub down in Marietta,” Allison explains. “When we’d just started out, it wasn’t uncommon for engineers to swing by our shop on their way home from work to get their tools modified.”

Fast-forward to the present, where Win-Tech has built strong relationships with Lockheed Martin, of course, but also with other companies both large and small in the aerospace, construction, and medical industries, just to name a few.

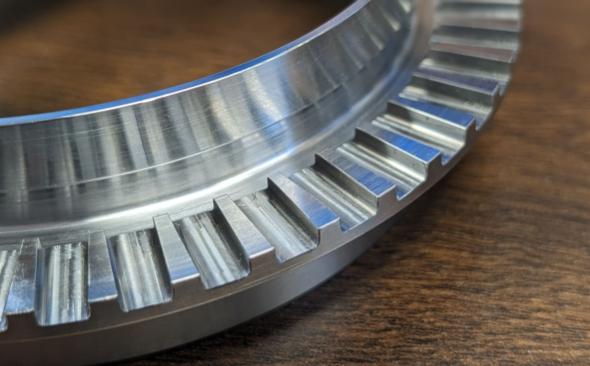

For these customers, Win-Tech’s expert team offers special tooling and precision machining (particularly tight tolerance machining) for a range of applications. Whether producing single pieces or high volumes, Win-Tech strives to exceed customer expectations while continually refining its approach to machine shop management.

For example, the company obtained an AS9100 certification and established a quality control process that meets the MIL-I-45208A standard—a necessity for doing business with the US government and many defense companies.

Taking Off with NTMA’s Network

When it comes to how to run a machine shop, Win-Tech often consults the NTMA network, of which it has been a member for over 20 years.

Allison tells us that “when Dennis [Win-Tech’s founder] joined NTMA, he did so to connect with other machine shop owners, to share ideas. He didn’t want to reinvent the wheel—he wanted to learn from and share his expertise with other shop leaders.”

Through NTMA, Win-Tech connects with other modern CNC machine shops that are facing similar challenges, allowing the team to solve nuanced, industry-specific issues without needing to start from scratch. “When we have questions,” Allison points out, “we can just jump on the NTMA message board and get recommendations and trustworthy references from other members.”

Win-Tech also benefits from face-to-face discussions at NTMA summits. As Allison detailed, “Every summit features roundtables and open conversations where members exchange ideas and solutions on key topics. These opportunities to share authentic knowledge are worth the price of admission, so to speak.”

Above all, Allison reminds us, “It’s just refreshing to know you’re not alone.”

Representing NTMA in the Southeast and on Capitol Hill

Win-Tech is also giving back to NTMA by taking on a leadership role in the Southeast and participating in its advocacy efforts.

As of 2024, for instance, Allison is NTMA’s Southeast region at-large trustee. “While there aren’t quite enough shops in the area for a formal chapter,” she tells us, “I’m looking forward to finding ways to increase membership and get people engaged on the national level.”

Allison knows just how important this kind of engagement is for the modern CNC machine shop. “I’ve participated in NTMA’s OneVoice efforts and been actively involved in the process of lobbying on important issues like taxes and workforce development,” she tells us. In addition to introducing her to other machine shop owners, this work has allowed Win-Tech to help shape the future of the industry by making its voice heard on Capitol Hill.

NTMA Brings Machine Shops Together Around a Shared Goal

Speaking of other NTMA members, Allison concluded that, “in a way, we’re competitors—but there’s really so much work to go around. Nobody can eat the whole pie! So, we all realize that the quicker we can attract more people to the industry, the better. That’s what NTMA really offers: a shared table where everyone has good intentions, where everybody wants to help each other.”

Interested in shaping the machining industry’s future? Become a member of the National Tooling & Machining Association today!