This article by Julia Hider originally appeared in Modern Machine Shop magazine.

Done improperly, automation can introduce more problems than it solves. Robot arms, pallet systems and other forms of automation are designed to replicate processes established by humans, so before introducing an automation system, shops need to ensure that their processes are solid. For Advanced Machining, a job shop near Tulsa, Oklahoma, preparation for a new pallet system entailed implementing a machine monitoring system, revamping the tool crib and creating new workholding to reduce setup times.

Advanced Machining is a sister company of Advanced Plastics, which CEO Scott Shortess’s father founded in 1979 as an industrial plastic distributor and fabricator. He started Advanced Machining when one customer asked if the company could start providing component parts instead of raw materials. “At the time he said, ‘I have no earthly idea how to machine parts, but we’ll figure it out,’” Shortess recalls. “So he purchased a couple Mori Seiki lathes in the early ‘80s, and we started working through it.” Eventually, Advanced Machining started taking on work for local aerospace companies. Focusing on high-mix, low-volume work, the company has since expanded into five-axis machining as well as the oil and gas industries.

A Path to a Pallet System

Interest in a pallet system dated back years, but leadership recognized that other changes were required first. “Automation is just going to replicate your process, whether it’s bad or good,” Shortess says. “So, obviously, we had to have a stable, predictable process.”

The first step on Advanced Machining’s path to a pallet system was implementing machine monitoring. Struggles with lead times and on-time deliveries had prompted the shop to start tracking machine utilization, but the process was less than efficient. “We used to go out on the shop floor with a smartphone, take a picture and then go back and calculate the graphs,” Shortess explains. The shop has since implemented FactoryWiz, which frees employees from gathering this data and making calculations manually.

The initial data showed low spindle utilization. Shortess says that, out of 8,760 hours, uptime percentages were in the high teens and low twenties. Advanced Machining had the capacity it needed, but long setup times, poor execution and inefficient workflows were eating away at uptime. The shop needed to find a way to enable employees to run more than one machine, reduce setups and improve process efficiency.

Tooling and Workholding

One area the shop targeted for improvement was its tool crib. Initially, when determining tool assemblies, the programmer would give the general type of tool (for example, a three-flute, ballnose endmill), and perhaps a specific brand. Shortess describes a “git ‘er done” mentality — choosing whatever tool will work instead of thinking about efficiency.

Now, the prevailing view is that building tool assemblies demands a more scientific approach. “There’s thousands, tens of thousands of different types of end mills that can do different things in different environments,” he says. “But to know the right one to pull and use is critical. That’s typically a human being making a decision.”

This decision is still made by people, but now it is informed by data: particularly tool life time studies conducted to figure out how long to let tools go before changing them. Establishing these tool limits is a challenge for a shop that does primarily high-mix, low-volume work because lack of long-term contracts (like those common in the automotive industry) makes tool life less predictable. “When you’re running five or 10 parts and you might never run them again, or you might run them a year, sometimes it’s hard to get consistency,” he says.

Now, when engineering defines a tool assembly, Shortess says that the tool crib treats it like a recipe. “When you do start going away from the recipe that you’ve proven works, it’s all downtime,” he explains. For example, substituting a four-flute end mill for a five-flute tool will require tweaking the program and slowing the machining process.

A consistent supply of tooling is essential to making this system work. “When tooling does expire, you have to have that supply chain support to make sure that the tool crib can go in and build a redundant tool for the shop floor, therefore reducing variability into the recipe,” he says. Consignment tooling has helped the shop manage its supply of tooling and ensure the tool crib has what it needs. “To be able to set up minimum and maximum on your high users helps a ton for having control of the consumable tooling.”

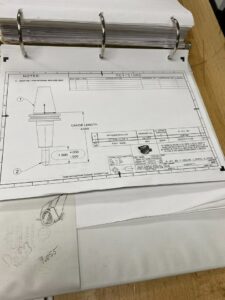

The shop also added a Zoller tool presetter and heat shrink toolholding from Haimer. Now, the engineering department creates a model of all tool assemblies needed for a job, including the consumables and EDP numbers (a five-digit number that helps identify cutting tools). All tool builds are kept in a three-ring binder in the tool crib, so the shop can reference them later upon receiving another order for a run of the same parts.

If a tool assembly is like a recipe, then this binder is like a cookbook. The tool crib attendant finds the correct recipe for the tool assembly, builds it accordingly and puts it through an inspection routine on the presetter. Once it passes, the tool goes out onto the shop floor.

A new workholding system also helped reduce setup times and improve spindle uptime. Replacing its vise-type workholding with a more flexible dovetail and windowpane-type system built in house has reduced setup times from hours to minutes. “There was one test that we did that was about an hour and a half setup time, and we were able to reduce it to like 10 minutes,” he says.

Pallet System

In 2019, the shop was finally ready for a pallet system. It installed a Flexible Manufacturing System (FMS) from Fastems with two Okuma MU 5000 five-axis machines and a KUKA robotic arm for machine tending. Advanced Machining’s system has 36 pallets that act as interchangeable subplates for the workholding system.

The FMS also includes a manufacturing execution system: Fastems’ Manufacturing Management Software (MMS). The program holds basic ERP data, including part number, quantity and due date. MMS also holds G code as well as information about setups, tooling and raw material. The system uses all of this data to schedule and execute jobs. It also notifies operators of any issues that would prevent a job from running (for example, if it doesn’t have raw material or if a tool needs to be replaced).

The FMS has been a good fit for the shop’s high-mix, low-volume aerospace work. These jobs are commonly in batches of 5 to 10 parts, with 2- to 3-hour cycle times and complex geometries including lofted surfaces and surface-profiled parts. As Shortess describes it, there is “hardly anything with a right angle on it.” Choosing rigid machines for the cell also enables Advanced Machining to focus more on cutting hard metals, such as titanium and 15-5, 17-4 and 13-8 stainless steels. These materials aren’t necessarily common for its aerospace customer base (which Shortess says is still an “aluminum world”), but this capability helps differentiate. “Not everybody can cut hard metals well,” he notes.

According to Shortess, the quality of parts coming off of the FMS is consistently good, as is the first pass yield. “We ran a part the first time on this a couple months ago, and another lot came through just this week,” he says. “We put it in the system and hit go, and it ran the entire lot with no nonconformances.”

The FMS has also enabled Advanced Machining to run lights out for the first time, although whether the pallet system runs unattended depends on whether the shop has proved out the part program. “It just kind of depends how stable the work is,” Shortess explains. “We’re introducing a lot of new work to it right now.”

It takes at least a couple of runs for the shop to feel comfortable running a part program lights out. Due to the constantly shifting demands of a high-mix workload, getting comfortable can take a while, even if a job’s part quantity is relatively high. “We might run a part but then we won’t run it for another six to eight months, so it’s hard to get the confidence level built up,” he adds. “In our business, it’s just on to the next, on to the next.” However, he describes a lot of the pallet system’s work as “semi lights out,” with very reduced direct labor input.

The team is still working on how best to use the system. Shortess describes its spindle utilization as a see-saw — it drops when the shop introduces a new part, and goes back up once the process is proved out. For Advanced Machining, these are not problems, but learning opportunities — opportunities that will be critical for plans to expand the shop and add another FMS. The second pallet system will include not just five-axis milling, but also four-axis HMCs and/or mill-turn machines as well as robotic deburring, parts washing, part marking and metrology. “We bought this to learn and, obviously, to make money on it too. That’s first and foremost,” he says. “But you’ve got to start somewhere.”