This article by Matt Danford originally appeared in Modern Machine Shop magazine.

Heidi and Bob Devroy claim they have been “blessed” in their rapidly diversifying business, but there is more to their success than luck or divine providence. Behind this couple’s outward humility is a combination of shopfloor expertise, business acumen and resolve that continue to flavor investments and filter into the culture of their 10,000-square-foot CNC machine shop, Prosper-Tech Machine & Tool.

“We figured we could either go down, or pick ourselves back up, shake it off and recognize that when one door closes, others can open.” – Bob Devroy, Prosper-Tech Machine & Tool.

This is not to suggest that the Devroys have not been fortunate. One of the first opportunities to evolve beyond the company’s automotive tooling roots knocked quite literally in 2017 in the form of a visitor seeking a machining process for a troublesome prosthetic assembly. With no prior contact with the shop, the man could have chosen among a variety of other potential subcontractors in and around Richmond, MI. Yet there he stood, offering a chance at what would become Prosper-Tech’s first medical contract. Now, a five-axis machining center runs overnight to churn out these and other comparable parts by the hundreds for inspection in a space newly dedicated to quality control.

Heidi and Bob Devroy say they never envisioned machining medial parts, let alone parts that might one day go into space, when they founded Prosper-Tech in 2007. All photos courtesy of Prosper-Tech.

Fortune seemed to smile on the shop again last year, this time in the form of a phone call. Assumed to be spam at first based on the caller ID, the number turned out to be legit. Again, someone needed a more cost-effective process for a difficult job. This time, the parts would be for one of the major commercial space companies. This work is now regular as well, produced mostly on one of the shop’s first-ever turning centers from difficult-to-machine superalloys.

Such opportunities are never guaranteed, and the specific strategies and technology investments that Prosper-Tech used to capitalize on them might not be practical to replicate at other shops. However, other shops that successfully diversify are likely to be similar to Prosper-Tech in a broader sense.

For one, standing out among more established competitors with initially broader service offerings requires highly skilled machinists. Prosper-Tech’s success is rooted in the skills of a team with decades of combined experience in building automotive plastic injection molds.

For another, preparation must extend beyond the shop floor. In this case, neither the medical nor the space opportunity led the company anywhere that it did not already seek to go. Rather, these opportunities clarified and accelerated pre-existing plans to scale the business.

Finally, the Devroys credit much of their success to intangibles. Specifically, they credit their faith — not just in their God, but also in the idea that a strong work ethic, a commitment to serving others and the continuous pursuit of personal and professional growth can lead opportunity to spring from crisis.

(Work)holding it All Together

The piston-and-housing assembly that became the shop’s first medical contract had stymied other suppliers. However, the banana-like portion of the piston proved to be ideal for a custom, on-machine finishing method that employees had originally developed to limit manual polishing of automotive plastic injection molds.

Machining a surface finish of 8 to 16 RA on the curved portion of this 303 stainless steel prosthetic foot piston component provided an opportunity to develop a standardized process and diversify into the medical industry. All images courtesy of Prosper-Tech Machine & Tool.

This kind of expertise had already driven expansion beyond the company’s initial customer base, which consisted mostly of industry contacts made during Bob Devroy’s long career at another moldmaking company. Prosper-Tech’s first parts had been cut in 2007 on some of that now-defunct company’s previous equipment in the family garage, where the Devroys started their own business amid deep recession and sudden, unexpected unemployment. “We figured we could either go down, or pick ourselves back up, shake it off and recognize that when one door closes, others can open,” Mr. Devroy says, recalling taking on roofing jobs on the side to keep the company afloat.

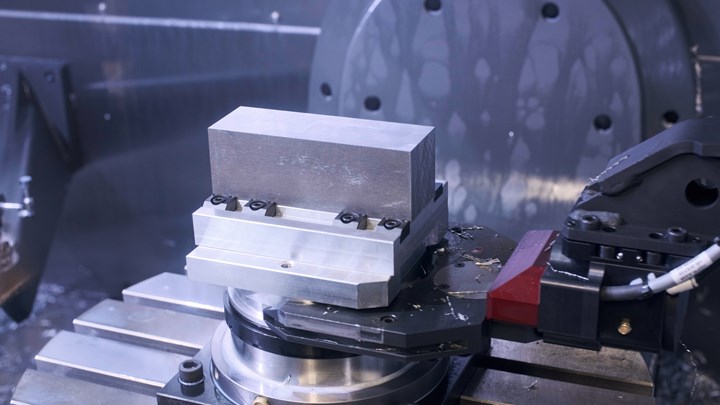

Standardized workholding enables transferring parts seamlessly from robot carousel to five-axis machining center to CMM without re-referencing locations.

For her part, Mrs. Devroy pursued a business degree while simultaneously working to grow the fledgling company. The couples’ hard work paid off, and the shop moved into its own facility in 2014. However, the Devroys’ growing customer base was still largely automotive. They had long recognized the potentially devastating effect of another downturn, and that meeting what they saw as core responsibilities to their children, to co-workers-turned-employees and even to the broader community would require diversifying the business. The chance to developa machining process for the artificial foot piston and housing could not have come at a better time.

Toolmaking expertise aside, the team’s thinking changed as Prosper-Tech took on additional work from its new customer. As Mr. Devroy puts it, “the little stuff becomes more important when you’re machining 500 parts versus one or two.” Nonetheless, previous experience provided valuable lessons as the process evolved. The current strategy is reminiscent of how many mold shops automate production of electrical discharge machine (EDM) electrodes. A carousel-style robot (a 60-station Erowa Robot Compact 80) sequentially feeds pallets loaded with blanks into a five-axis machining center (a Haas UMC750 with side-access auto-door). A common interface between the pallets, the robot and the machine table ensures repeatable enough positioning to load the carousel and step away.

Each pallet features pockets machined to accept the various clamps and other devices that secure specific, standardized blank sizes for 16 total part numbers (for example, the same fixture might hold a 2” x 2” x 6” blank or a 1.5” x 2” x 6” blank).

Mr. Devroy says this modular pallet system is the “glue” that holds short-run production together, even beyond the machining center. “We can take that pallet right to the CMM without losing any time or money switching fixtures,” he says.

Ready for Launch

Prosper-Tech purchased its CMM (a Hexagon 4.5.4 SF with articulating head) at the same time as the robot and pallet system. From there, the shop focused on process development, particularly obtaining IS0 9001 certification for the new quality control process.

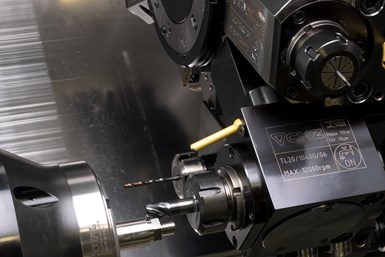

New work opportunities have led to new equipment investments such as this live-tool lathe. Purchased from Merrifield Machinery Solutions, the EuroTech CMZ TA20 is among the shop’s first non toolroom turning machines.

However, another quality control certification has played an equally important (or perhaps greater) role in Prosper-Tech’s evolution. Had the shop not undergone an AS9100 aerospace audit only one month before the fateful, seemingly random phone call from the commercial space company, that call probably would have ended immediately, Mrs. Devroy says. Instead, Prosper-Tech got another chance to test its mettle on a new variety of work: mostly prototype fittings with various square- and hex-shaped geometry that are produced in small lots and subject to frequent design revisions.

Machining these parts effectively from materials including nickel-based alloys such as Inconel and Monel would require the shop’s largest investment in a single piece of equipment to date: a turn-mill (EuroTech CMZ TA20) with a 12,000-rpm live-tool turret and heavy-duty box ways. None of the staff had much experience with CNC turning outside the toolroom, but Bob Devroy says he relished the chance to try something new.

In fact, he’d been waiting for that chance. A year prior, in 2018, Heidi Devroy accepted a nomination to participate in Goldman Sachs’ 10,000 Small Businesses program, which supports entrepreneurs with education, capital and other resources. During her research for an individual “growth project” that could apply to her company, Mrs. Devroy had what she calls a “lightbulb moment.” According to data in the IBIS World Industry Report for Machine Shop Services, Prosper-Tech had a key weak point compared to other, similar businesses: lack of turning capability that had led to missed quoting opportunities over the years. Potential for turning beyond the space parts increased confidence about investing in a more capable machine than the Devroys initially envisioned, as well as a CNC laser marker.

Devroy (left) and the rest of the Prosper-Tech team continue to innovate with work slated for the new turn-mill. One upcoming change is likely to be replacing the threading tool in the tool turret with thread-rolling heads that are better suited for nickel-based alloys.

The 10,000 Small Businesses program also provided a more direct path to diversification. Another program participant that year was the owner of another woman-owned small business: Mettle Ops, a research, development and fabrication company focused largely on defense applications. Together, the two companies formed a joint venture: Mettle Craft, one of four businesses selected for a 5-year, $19 million opportunity to support the production of military ground vehicles.

Like AS9100 certification, the timing could not have been better. By the time the Coronavirus pandemic began to shutter the economy – taking a quarter-million-dollar mold contract from a major automotive customer along with it – defense parts comprised about 15 percent of the shop’s work. The call from the space company came just a few weeks later. “We ended 2020 surprised and humbled with the makeup of our work,” Mrs. Devroy says. “In a turbulent year to say the least, our sales ended up being 33 percent medical, 23 percent automotive, 23 percent defense, 15 percent space and 6 percent other — a very nice, diversified balance going into the new year.”

Keeping the Faith

The Devroys’ approach to running their company has been driven by a consistent set of underlying principles and philosophies. Examples include:

Put Yourself Out There. The initial call from the space company was not as random as it initially seemed. As it turned out, a student who had toured Prosper-Tech in 2014 as part of the company’s regular collaboration with local schools ended up working for the space company. This tour made enough of an impression that the shop came to mind years later when the need arose for a new supplier.

Other examples of active participation in the broader manufacturing community abound. The 2018 International Manufacturing Technology Show (IMTS) in Chicago provided an introduction to the robot and five-axis machine. The shop is a member of Automation Alley, a nonprofit center for private-public partnerships to fuel manufacturing innovation, as well as the Aerospace Industry Association of Michigan and the Michigan Manufacturers Association. A website populated with professional video about the company and its processes exemplifies the Devroys’ belief in the power of marketing.

“These parts are going to end up on somebody’s body. Our soldiers will depend on these parts. Some of what we’re developing could one day end up in space.” – Heidi Devroy

Have a vision. Although the Devroys never envisioned turn-milling parts that might one day end up in space, both aerospace and turning capability were already part of the plan when that opportunity presented itself. Similarly, the first defense work was not for Mettle Craft, but for general production part contracts won around the same time that the shop implemented the five-axis machining cell and CMM. “You have to envision where you want to be, then ask what it’s going to cost and whether it will be worth it,” Mrs. Devroy says. “If it’s too much, then rethink that end point.” (For Prosper-Tech, of course, the space opportunity enabled investing more than planned).

Optical comparators are just one example of recent, significant investments in quality control. This equipment was purchased at the suggestion of a new quality manager, who was hired for his experience at large aerospace companies.

Act like a franchise. One key lesson of the Small Business Program was the importance of standardized processes, Mrs. Devroy says. “Treat the business like its McDonald’s — like you’re going to franchise it.”

At Prosper-Tech, this means “following written procedures and focusing on making them better,” she says. For example, she says the shop has developed a particularly robust system for material verifications and certifications. On the shop floor, “Even the coolant concentration must be exact” for some of the shop’s medical work, Mr. Devroy says.

Commit to Personal Growth. “Everyone is like their own business,” Mr. Devroy says. “I have a certain profit margin I need to meet in my household, and I need to strive to get the skills and education I need to further that business and my family in general,” Mr. Devroy says.

Hiring people who think the same way ingrains these values in the company culture. “(Employees are) not just succeeding for us,” Mrs. Devroy says. “We want to help get that training someone needs, even if they end up working somewhere else later. We ask (prospective hires) about personal goals outside of work, because that’s important for who we want to attract.”

Bob Devroy (right) works with Roy Keuning, who joined through a U.S. Department of Labor (USDOL) apprenticeship program conducted in partnership with St. Clair Community College.

Maintain Perspective. The Devroys say they are driven by a deep sense of responsibility, to their customers and beyond. “These parts are going to end up on somebody’s body,” Mrs. Devroy says. “Our soldiers will depend on these parts. Some of what we’re developing could one day end up in space.”

Whatever opportunities the future brings, the couple believe they will be rewarded for remaining true to their core values and doing what they think is right, both in manufacturing and in life. “God put us together, and we have the unique talents to make this work,” Mrs. Devroy says.